Increased revenue and margins through process redesign

Situation:

An automotive supplier sought to improve costs and customer win rates. Core issues included tooling center cost overruns and organizational misalignment.

Actions:

- Implemented Results Driven Management process across the entire value chain: sales, quoting, program management, project management, tooling, and pre- and final production

- Provided interim management of the tooling center Aligned organization cross-functionally and implemented roles and responsibilities

- Implemented targeted costing program that achieved >35% cost savings through engineering design changes and improved tooling costing

- Developed sales force management tools

- Established continuous improvement culture

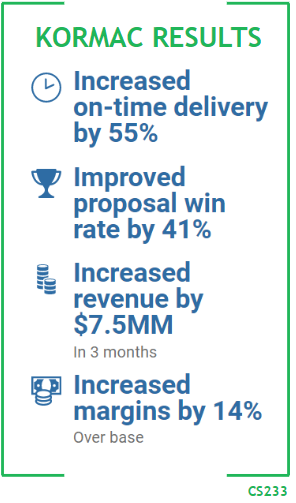

Results: Increased revenue by $7.5MM and improved margins by 14% over base.