Transformed maintenance shop quality and culture

Situation:

A high-speed automotive stamping maintenance shop lacked direction, metrics, and standardized processes, resulting in massive downtime on its production equipment.

Actions:

- Delivered a complete Die Maintenance (DM) Results Driven Management System of processes, documented best practices, behaviors and tools, including work orders, planned work, backlog identification, work order history, KPIs, trends, problem tools, and repetitive failures by various time periods

- Installed on the shop floor a DM Visual Management Board highlighting KPI targets and results for the week by day, as well as historic trend information for the past week and 4-week periods

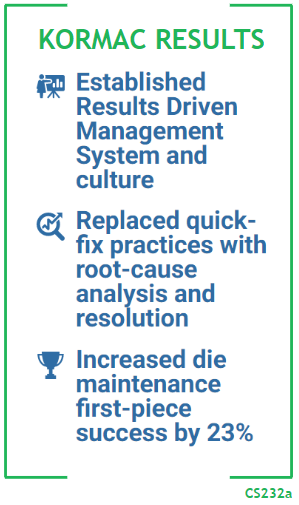

Results: Enhanced Die Maintenance shop quality, culture, and morale. Replaced quick-fix practices with strategic, root-cause analysis and resolution of repetitive failures.