Evaluated and developed third-party component suppliers

Situation:

A global Oil & Gas heavy equipment manufacturer lost critical suppliers when the 2008 economic crisis drove many small machine shops out of business. The resulting vacuum in its supply chain reduced OTIF to less than 60% and created a backlog of customer orders in excess of $125 MM.

Actions:

- Assessed current state, especially the effectiveness of management approach and strategy

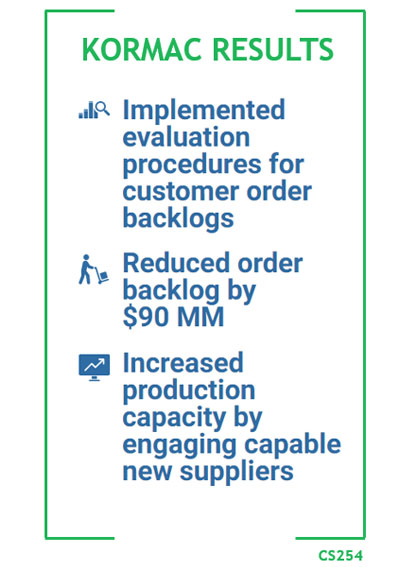

- Implemented a new approach to evaluating customer order backlog based on Order Value, Past Due Number of Days and Difficulty to Complete

- Identified key suppliers and potential untapped suppliers with the capability and capacity to fulfill top priority customer orders

- Drew contracts with new and existing suppliers to ensure capacity availability

- Worked with the client to develop accelerated suppliers’ training and quality control processes and procedures

Results: Reduced customer order backlog to $35 MM and increased OTIF from <60% to 85%.