Rationalized facility footprint and labor requirements

Situation:

An Oil & Gas services company wanted to improve overall efficiency through facility and labor cost reductions while improving quality and productivity.

Actions:

- Developed comprehensive plan to reduce rooflines and space requirements through consolidation and best practice implementation (Lean, 6S, Standard Work, Visual Factory, Optimized OEE, improved warehousing and supply chain operations)

- Trained client workforce on Lean principles to ensure culture change and sustainability

- Implemented 6S throughout client operations

- Developed detailed move plans for facility relocations

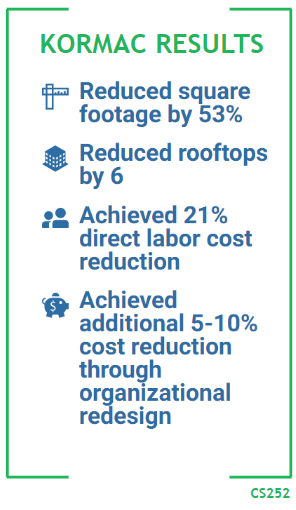

Results: Reduced square footage, rooftops, and labor costs. Streamlined supply chain, simplified the organization, and ensured consistency through standard work application.