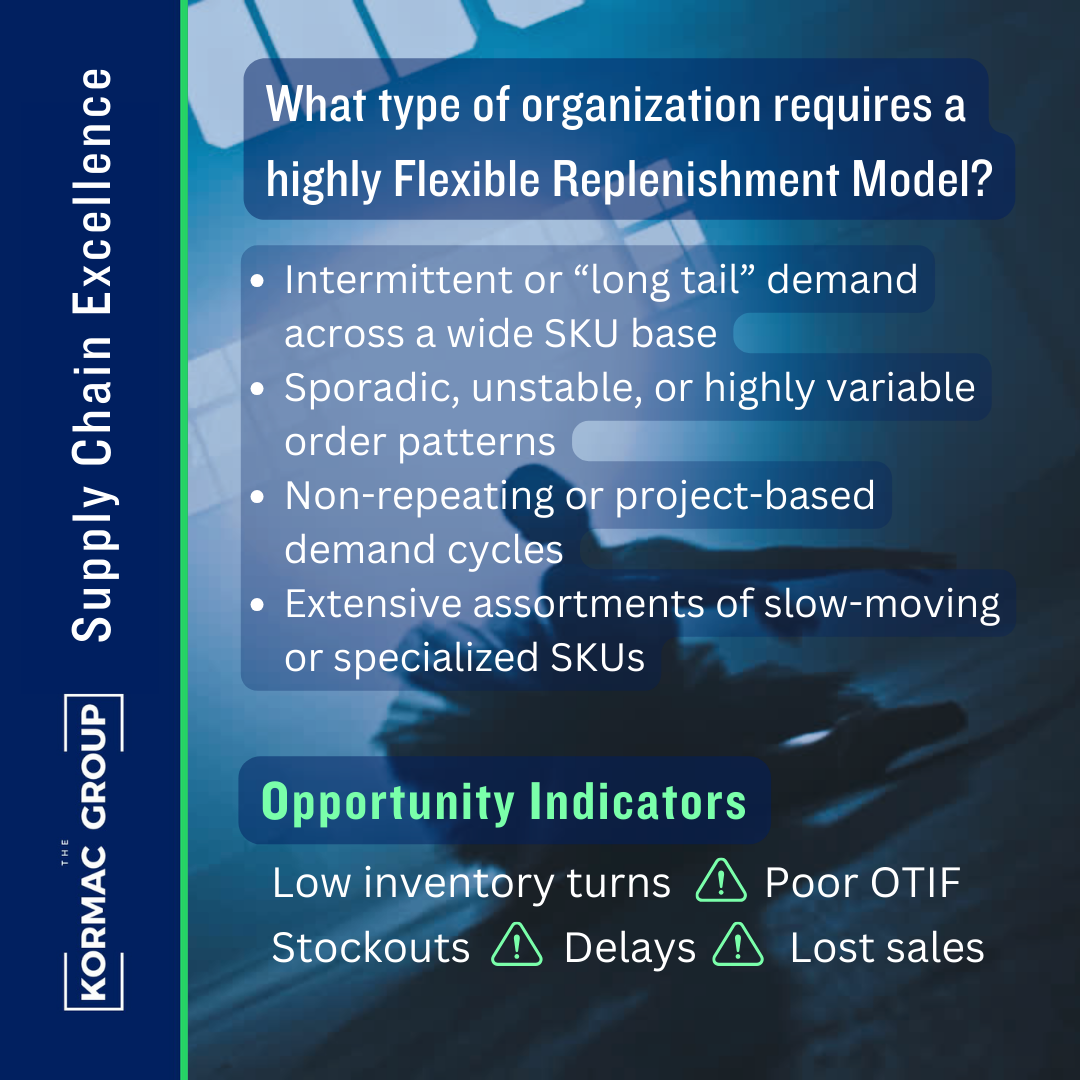

Flexible Replenishment Models

For Unpredictable Demand Across Wide SKU Base

Flexible replenishment models—leveraging historical data, real-time analytics, and demand variability—enable companies to maintain service levels without tying up working capital in excess inventory. We help our client partners build tailored, data-driven replenishment processes that boost both efficiency and customer satisfaction….

![Cost Management Rebalancing the margin tug-of-war Does your organization struggle to achieve financial goals in an increasingly volatile marketplace? [iconography of two teams playing tug of war, with the target margin in the middle. Text above the image reads "Kormac Rebalancing"] Cost Pressures: Labor, Materials, Logistics, Real estate, Technolgy Market Pressures: Pricing, service delivery, quality, lead time, social responsibility Kormac's Surgival Strike Methodology™ delivers the agility you need to meet your financial objectivers.](https://kormacgroup.com/wp-content/uploads/2022/10/cost-management.jpg)