Kormac Insights

Inventory Intelligence

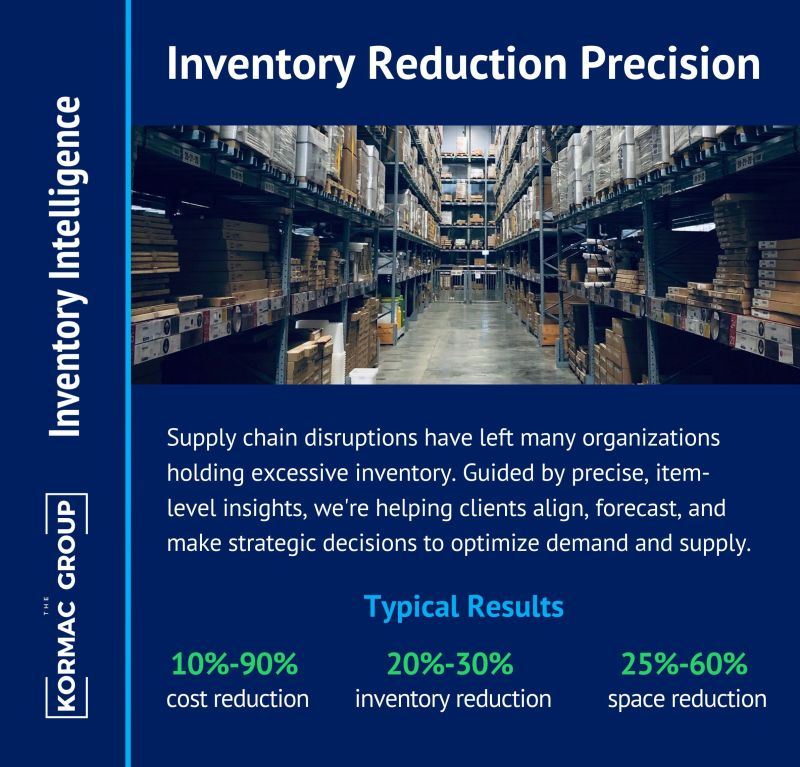

Inventory Reduction Precision

As supply chain disruptions ease, many organizations are left holding excessive inventory accumulated during the turmoil. Our Inventory Intelligence Surgical Strikes provide a path out of the wilderness toward optimized inventory and availability.

While inventory executives can typically slice and dice data to reveal relative performance and volumes, they often lack the ability to determine precise parameters on a per-item basis to achieve desired outcomes. For example, adjustments to lead time, supply reliability, and replenishment frequently offer opportunities to improve customer service levels and on-time-in-full rate (OTIF) while minimizing inventory levels. Dramatic and swift transformations occur once refined parameters are uploaded to the ERP system.

To sustainably improve inventory turns and convert improvements to net inventory cost reduction, we:

• Perform sales and usage inventory data analysis to support immediate, tactical inventory optimization priorities, as well as long-term, strategic inventory planning and alignment

• Review existing SIOP processes to determine existing demand and supply alignment, including communication and escalation protocols necessary for planning on extended horizons

• Implement process mapping, gap analysis, and gap closure priorities

• Develop precise, item-specific inventory strategies based on sales and usage volume and volatility, as well as broader strategies by business unit, item class, item type, geography, etc.

• Implement data-driven recommendations to balance inventory, costs, turns, and service levels

To learn more about how Kormac helps clients align, forecast, and make strategic decisions to optimize demand and supply, we invite you to view a few of our case studies: