Kormac Insights

Automotive Aftermarket

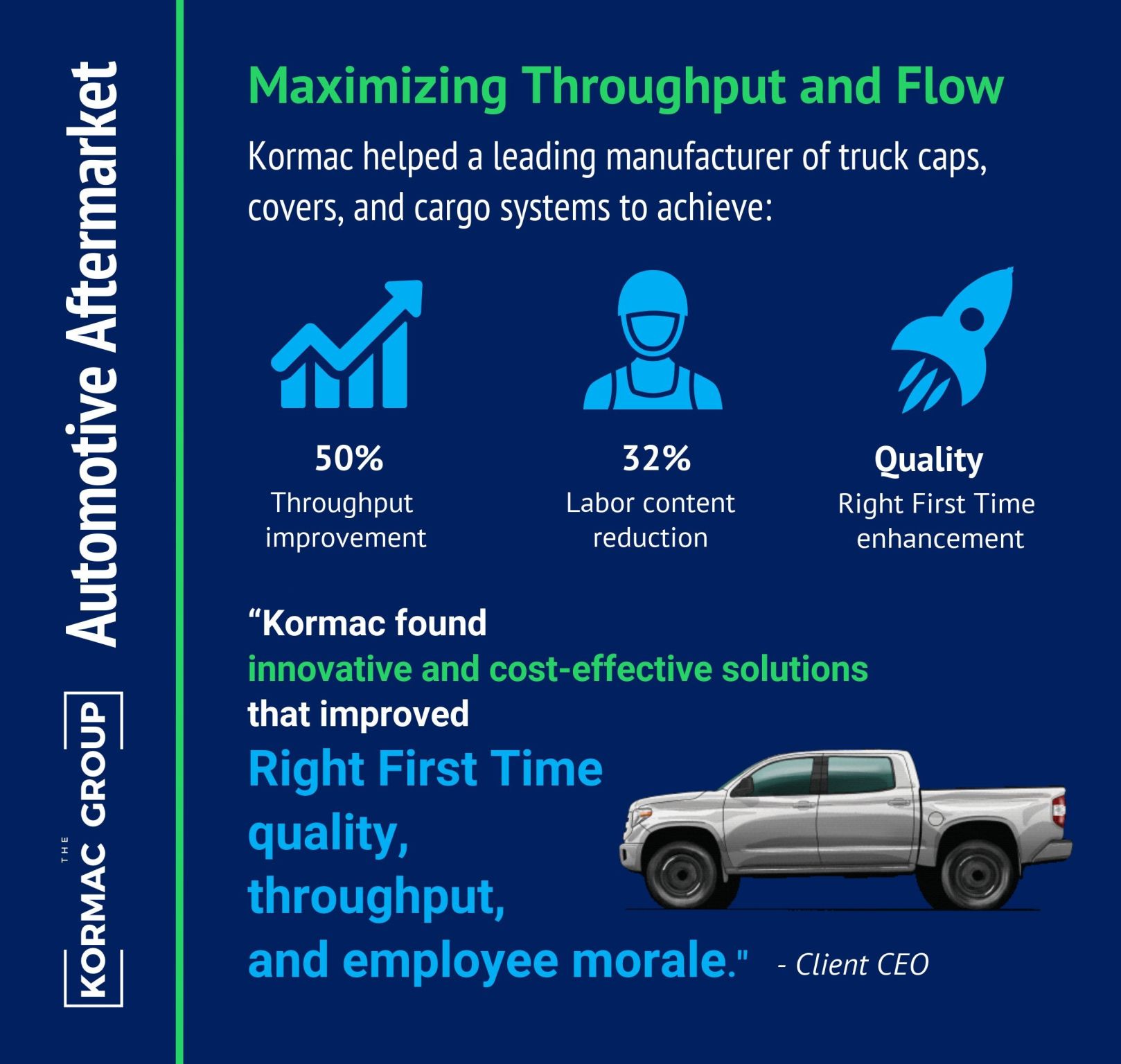

Maximizing Throughput and Flow

A leading automotive aftermarket manufacturer was facing large impending order volumes and turned to Kormac for help in improving throughput, quality, and facility flow. Together, we developed a future vision for one-piece flow through their entire operation. Because new equipment proved cost prohibitive, Kormac and the client team sought to improve the shop flow with existing equipment and minimal disruptions.

We began by focusing on the two most labor-intensive areas of the facility, which were bottlenecks to efficient flow. Kormac developed standard work, labor crewing, and innovative approaches to improve output from under 30 units per day to over 45 units consistently. We also reduced labor content by 32% per unit. Says the CEO, “The Kormac Group found innovative and cost-effective solutions that improved Right First Time quality, throughput, and employee morale.”

Key outcomes:

- Improved flow

- Reduced labor content by 32%

- Increased throughput by >50% (from <30 units per day to 45+)

- Improved Right First Time quality through reduced handling and damage of units during the manufacturing process