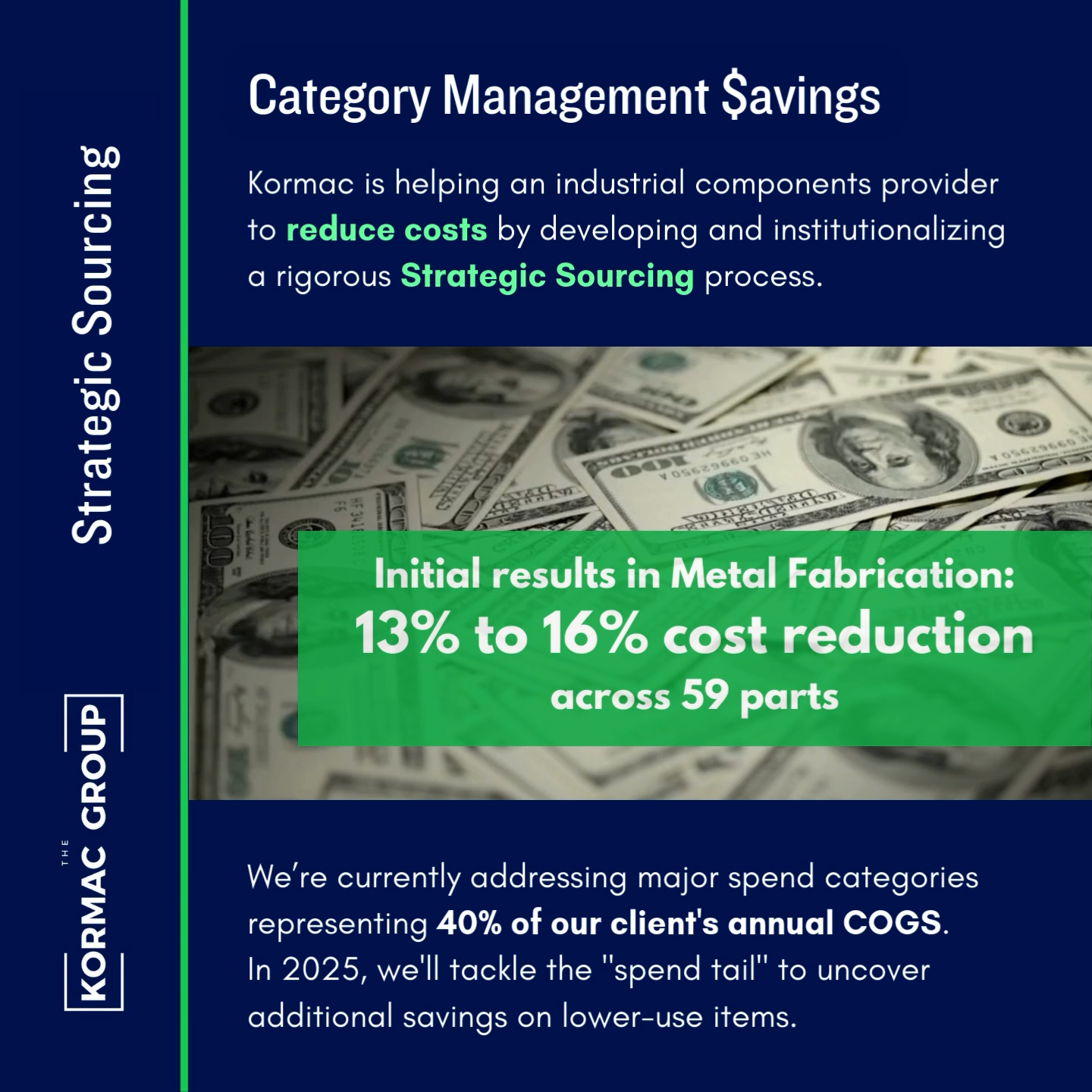

Strategic Sourcing

Category Management

We recently partnered with a leading industrial components provider to reduce costs by developing and institutionalizing a rigorous Strategic Sourcing process. In the first spend category, we immediately revealed a 13% to 16% cost reduction opportunity. We’ll soon address major spend categories representing 40% of our client’s annual COGS….

![Nearshoring to Mexico Nearshoring: ¡Vamos a México! Driven by federal incentives, geopolitical risk, and pandemic aftershocks, restoring and nearshoring continue apace. [Screenshots of various article titles about restoring and México] Kormac's senior operational experts have diverse experience designing, launching, and operating manufacturing facilities south of the border](https://kormacgroup.com/wp-content/uploads/2023/03/Mexico.jpg)