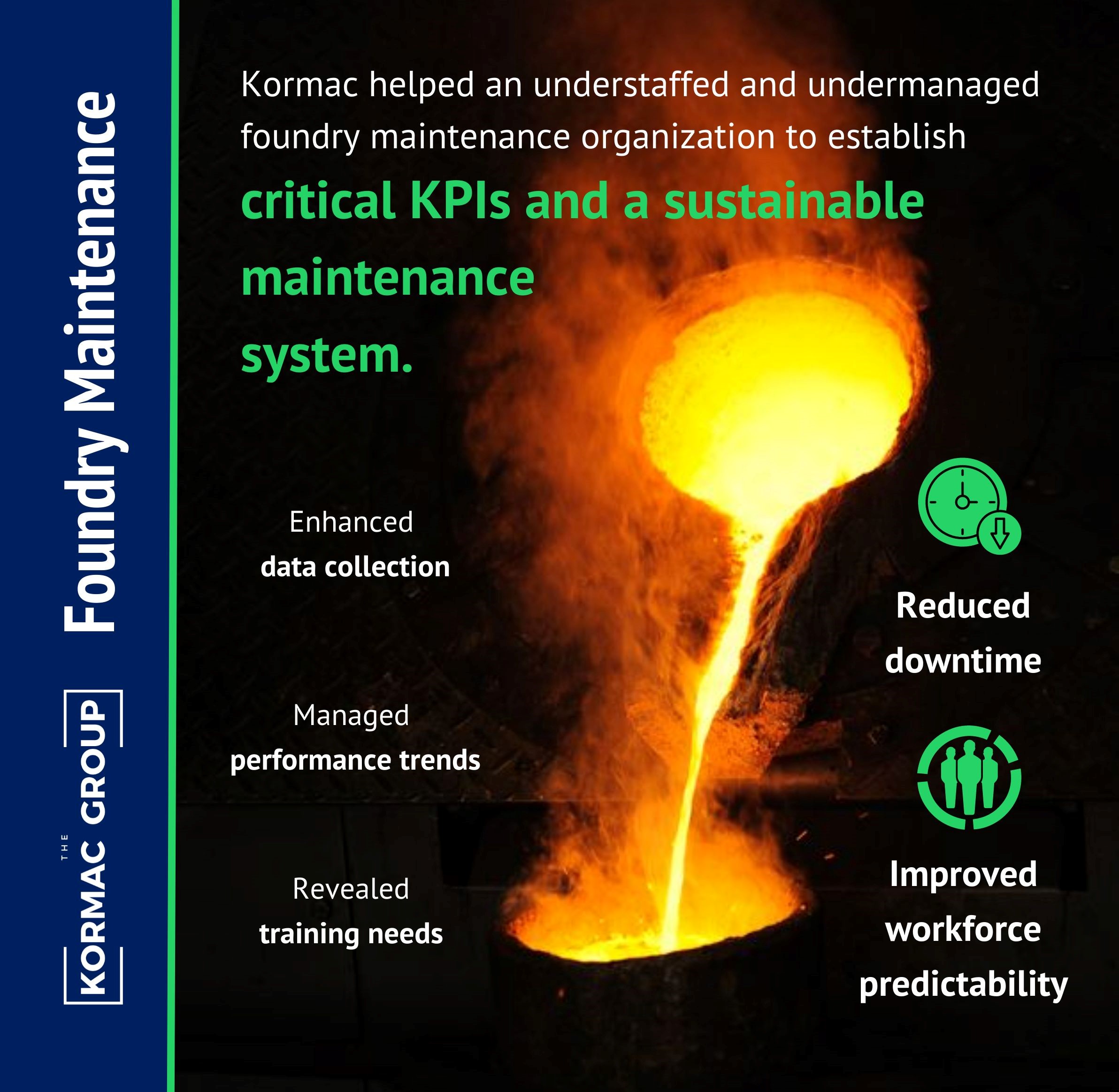

Foundry Maintenance

Kormac helped a foundry maintenance operation establish critical KPIs and a sustainable maintenance system

A leading supplier of metal components to the mining industry was struggling with manufacturing variability in its foundries. The president turned to Kormac for help in improving operational stability and predictability, including maintenance, operations management, and employee training and retention. Our initial foundry analysis revealed an understaffed and undermanaged maintenance...

![Nearshoring to Mexico Nearshoring: ¡Vamos a México! Driven by federal incentives, geopolitical risk, and pandemic aftershocks, restoring and nearshoring continue apace. [Screenshots of various article titles about restoring and México] Kormac's senior operational experts have diverse experience designing, launching, and operating manufacturing facilities south of the border](https://kormacgroup.com/wp-content/uploads/2023/03/Mexico.jpg)

![Interim Leadership Transforming a Plant as Interim GM When an integrated contract manufacturer lost its GM, Kormac provided a skilled interim leader Client Gratitude: Farewell messages to Kormac GM from dozens of plant employees [overlayed on top of image of the letters] On site for 10 months, our interim GM dramatically improved plant performance and morale](https://kormacgroup.com/wp-content/uploads/2022/12/interim-leadership.png)